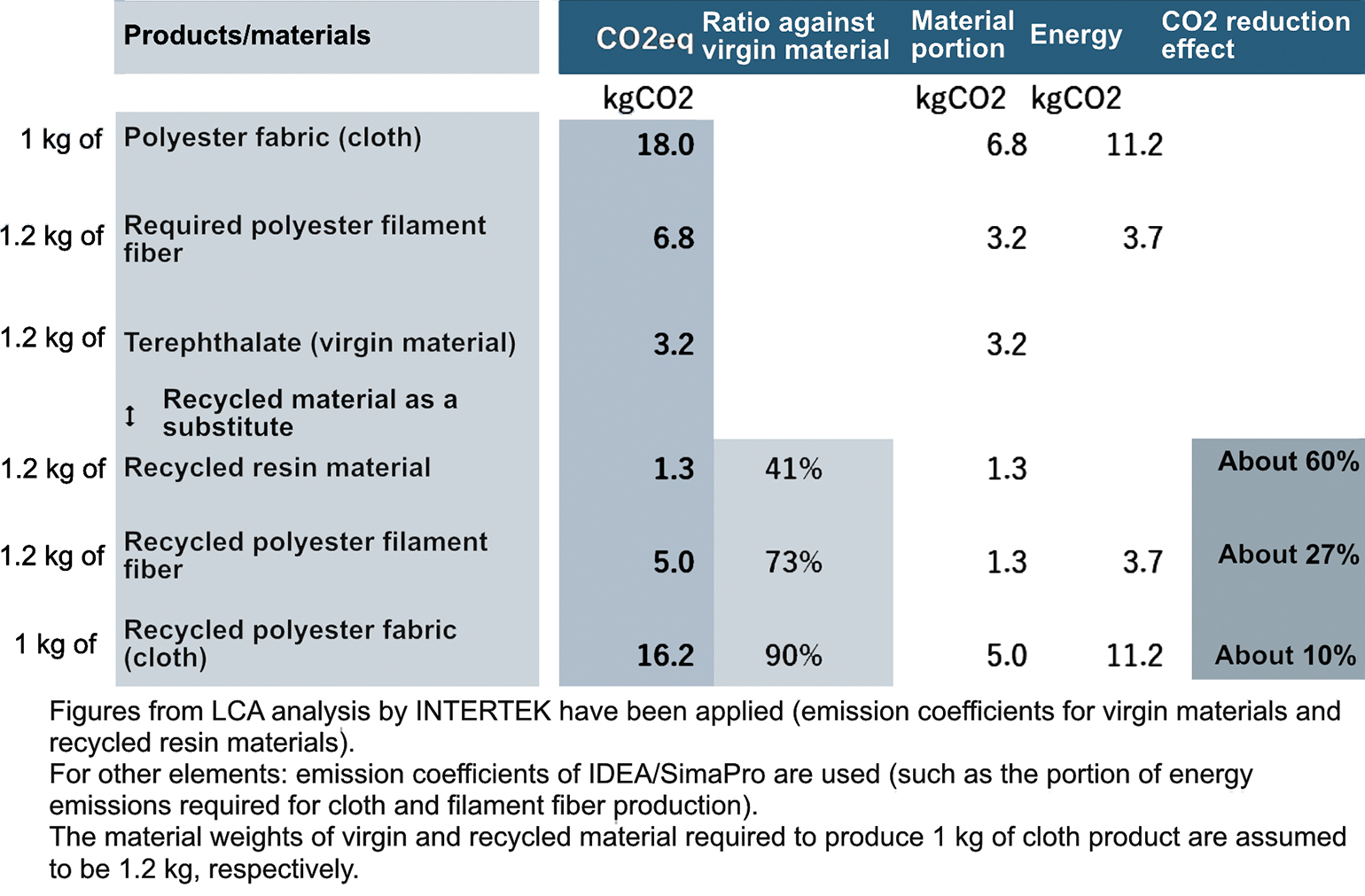

At the material level, replacing virgin polyester with recycled PET provides a relatively large reduction effect of around 60%. As processing continues, the reduction effect lessens, but even at the fabric stage a reduction effect of about 10% is still recognized. The reduction effect further diminishes for units of clothing, but there is still a significant difference compared to virgin material.

Comparison of CO2eq emissions

from virgin polyester and recycled polyester (materials/products)

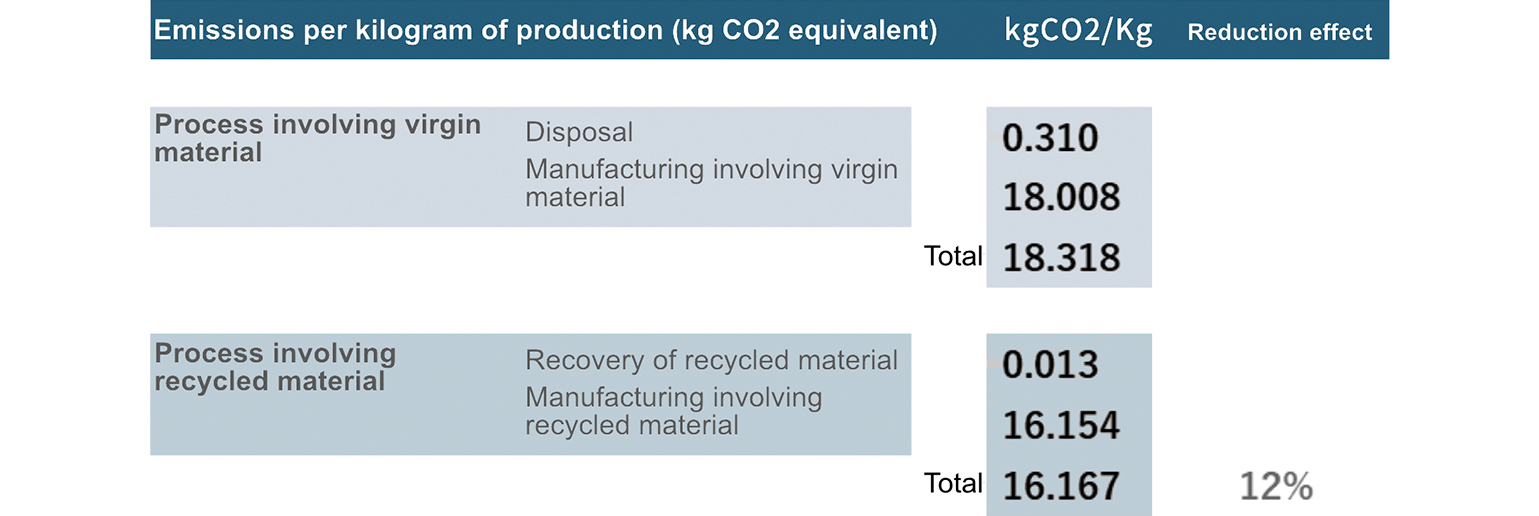

Comparison of CO2eq emissions

from virgin polyester and recycled polyester (corporate)

Calculation of the yearly reduction effect based on Toyoshima’s annual usage amount (total of 20,000 tons of polyester clothing). Analyze the differences in 1kg for both processes (2 cycles) and expand the results to calculate annual usage.

Virgin Material Processing: Disposal (one time) + Second manufacturing process

Recycled PET Processing: Transport of collected materials + Recycle manufacturing process

Analyze the differences in 1kg for both processes and expand the results to calculate annual usage. 1.0755kgCO2/kg (18.318-16.167)/2*20,000=21,510t (reduced amount of C02eq emissions that slightly exceeds the annually handled weight). If all the polyester handled is changed to recycled materials and one piece weighs 250g, then about 270gC02eq emissions will be reduced per piece.

- Sources:

-

Application of INTERTEK’s numerical values for LCA analysis (emission factors from virgin material/recycled resin material)

Using emission factors from IDEA/SimaPro (emissions and so on, from energy required to manufacture fabric/filament)

Assumption that for both virgin material and recycled material, the weight required to manufacture 1kg of fabric products is 1.2kg

Calculated by CARBON FREE CONSULTING CORPORATION based on data provided by Toyoshima