The impact that the fashion industry has on the environment has been a big issue around the world.

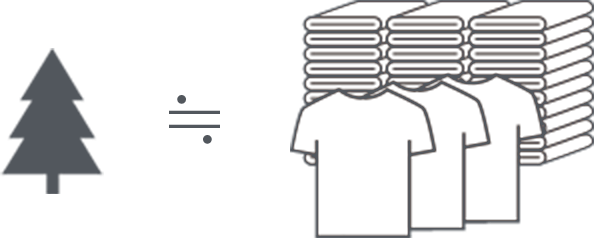

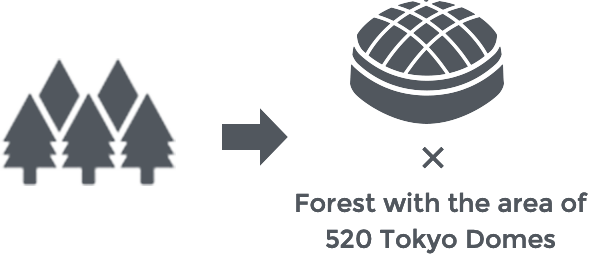

The Ministry of Environment reported that manufacturing processes, from material procurement to spinning and sewing clothing, to product transport, are responsible for emitting approximately 90,000 tons of C02 and using around 8.3 billion m3 of water per year. Additionally, 508,000 tons of clothing are discarded in Japan annually. Calculated per day, this is the equivalent of enough to fill 130 heavy-duty trucks.

“TecRecyc” is a global recycled material project that aims to lessen the burden on the environment. Focusing on three materials, polyester, nylon, and acrylic, TecRecyc has accepted the challenge of lowering the environmental impact of the fashion industry by reducing CO2 emissions through reusing previously discarded materials.